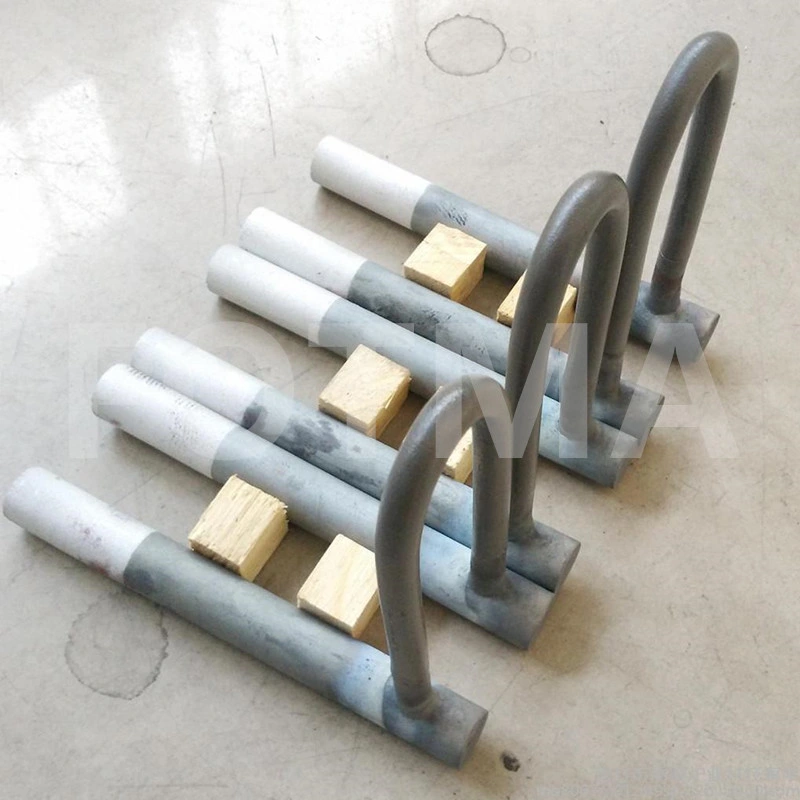

High Temperature L Bent 90 Degree Mosi2 Kilns and Furnaces Heating Elements

Basic Info.

| Model NO. | L Bent |

| Shape | L Bent |

| Material | Molybdenum Disilicide |

| Shipment | by Sea or by Air |

| Warranty | 3 Months |

| OEM Service | Available |

| Volume Density | 5.5-5.6g/cm3 |

| Transport Package | Polywood Case or as Customers′ Requirements |

| Specification | Customized MoSi2 Heater |

| Trademark | FOTMA |

| Origin | China |

| HS Code | 85168000 |

| Production Capacity | 10000 Pieces/Year |

Packaging & Delivery

Package Size 50.00cm * 50.00cm * 50.00cm Package Gross Weight 10.000kgProduct Description

L bent MoSi2 heating elements1. High purity MoSi2 heating element, for various electric furnaces, especially dedicated for high purity furnace2. Max. working temperature 1800 ºC3. Long life combined with ease of replacing failed elements contributes to a high degree of utilization of the furnace and low maintenance costs.5. New and old elements can be connected in series6. High power concentration may be applied7. Can be used continuously or intermittently8. Fast ramping

AdvantagesThe product has the capabilities to be resistant to oxidation and automatically repair, suitable for continued use in any kind of oxidizing atmosphere.The product is shaped in hot-working process, which keeps the base material in good tenacity and plasticity at high temperature. The geometrical figure, standard, and dimension are canonical, may produce any special shape and any dimension to meet the customer requirement.Because of the special technology, welding spot is fast and have shock resistance, which dramatically reduced the damaged probability of welding spot by electric current, as well as transit and installation.High density increases its electrical conductivity. The characters of faster warming and power consumption are low, which reduces production costs.Good appearance quality and tenacity, high mechanical strength.A protective layer of quartz glass is compact and has good adhesion with the substrateExcellent high-temperature strength which is not easy to deform in use

Physical Properties

| Bulk Density | Bending Strength | Hardness | Water Absorption | Heated Elongation | Fracture Toughness | Compression Strength |

| ≥5.8g/cm3 | 350MPa | 9.9GPa | ≤0.2% | ≤4% | 4.5MPa.m1/2 | 650MPa |

Chemical PropertiesMoSi2 Heating Element has the ability to withstand oxidation at high temperatures. This is due to the formation of a thin and adhesive protective layer of quartz glass (SiO2) on the surface. When the element temperature is over 1700ºC, the SiO2 protective layer which melting point is 1710ºC was fused, and because of the surface tension, it fused into drops, which is useless. However, when elements continue working in oxidizing atmospheres, the SiO2 protective layer is spontaneously rebuilt.Notice: It is no good to use Molybdenum Disilicide Heating Element for Long-term within a range of 400-700ºC, otherwise the element will be powdered by the strong low-temperature oxidation.

Indicators in Different Atmospheres

| Atmosphere | TC1700 | TC1800 | MR1800 | TC1850 |

| Air | 1700 | 1800 | 1800 | 1850 |

| Nitrogen | 1600 | 1700 | 1700 | 1750 |

| Argon, Helium | 1600 | 1700 | 1700 | 1750 |

| Dry hydrogen, dewpoint -80ºC | 1150 | 1150 | 1150 | 1200 |

| Moist hydrogen, dewpoint 20ºC | 1450 | 1450 | 1450 | 1500 |

| Exodus (Ex. 10% CO2, 5% CO, 15%H2) | 1600 | 1700 | 1700 | 1750 |

| Exodus (Ex. 40% H2, 20% CO) | 1400 | 1450 | 1450 | 1500 |

| Cracked and partially burnt ammonia | 1400 | 1400 | 1450 | 1500 |

The cold ends (Lu) of the Moly-D Elements can be bent 30A., 45Ao or 90A0. This permits the installation of more than one layer of elements on a wall of a furmace with a high chamber. Most are bent in the cold end (Lu) but they can also be bent in the hot section (Le).

Molybdenum disilicide MoSi2 heating elements are resistance type heating elements made of a dense ceramic- metallic material which can produce furnace temperatures approaching 1800°C. Although more expensive than traditional metallic elements, MoSi2 elements are known for their longevity due in part to a protective quartz layer that forms on the surface of the element"hot zone" during operation. Duralite MoSi2 elements are made to industry standard established resistance values, dimensions and geometries, and therefore are interchangeable with other manufacturers of molybdenum disilicide elements. The key difference between STA MoSi2 and other MoSi2 suppliers is that STA MoSi2 elements are exceptionally priced.